4M Series

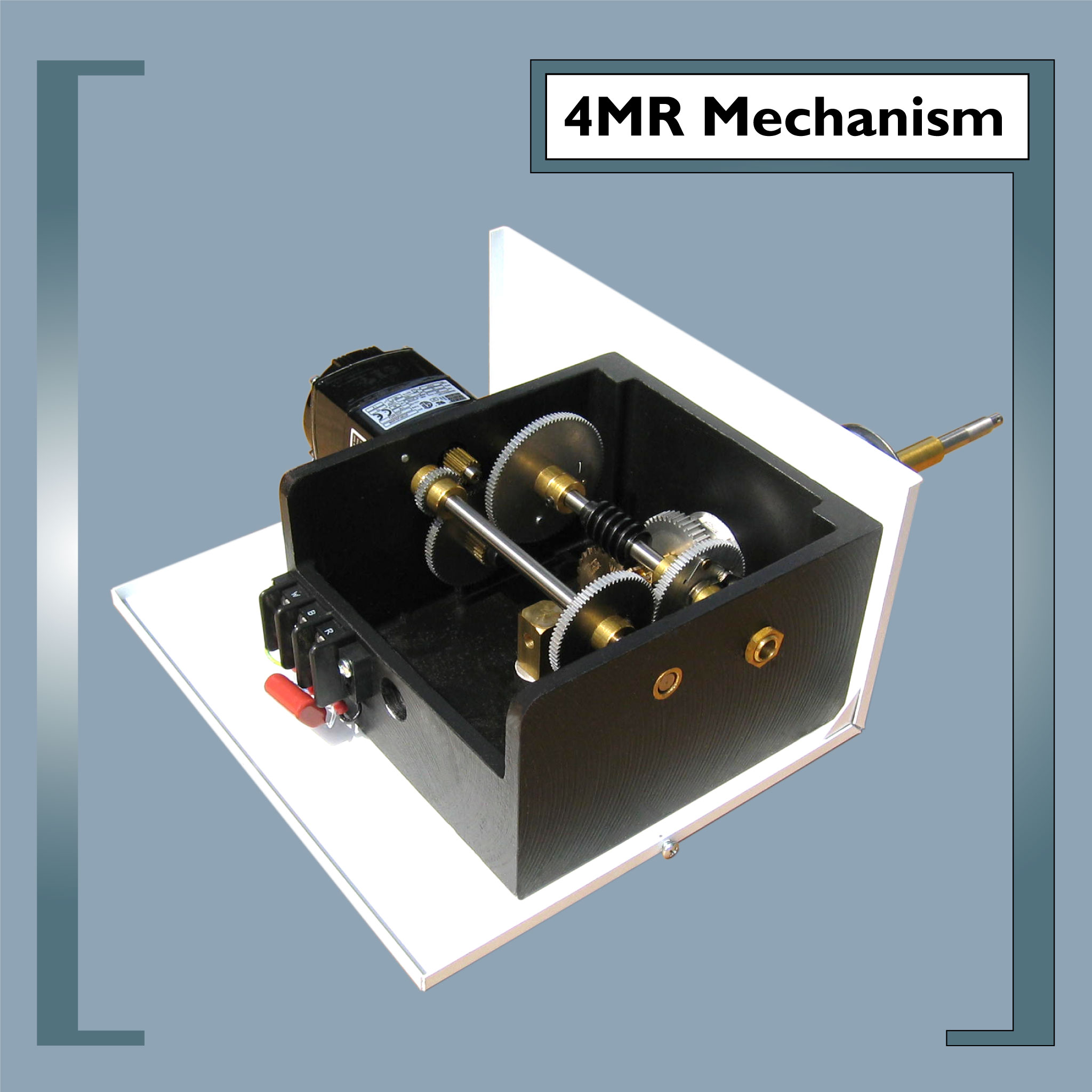

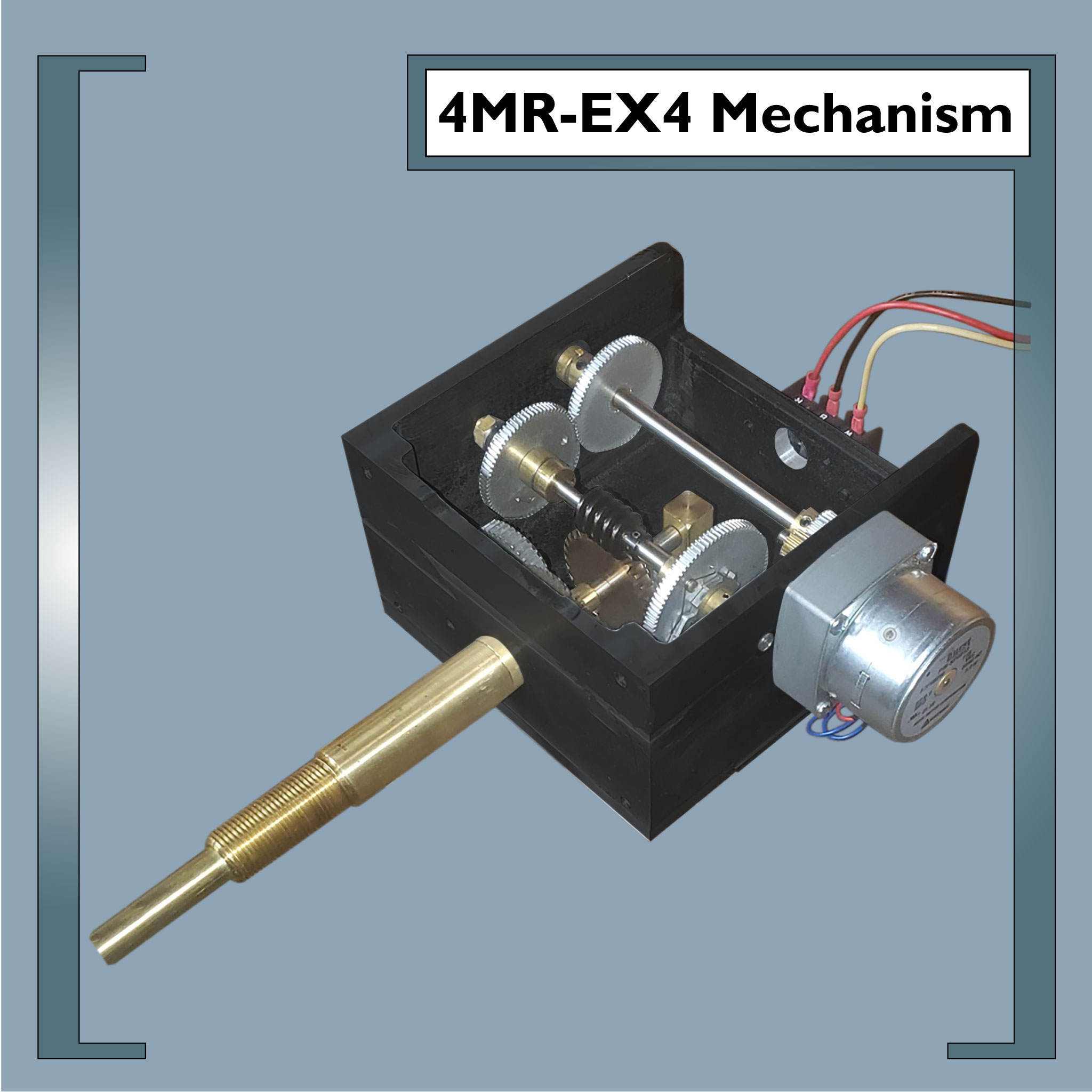

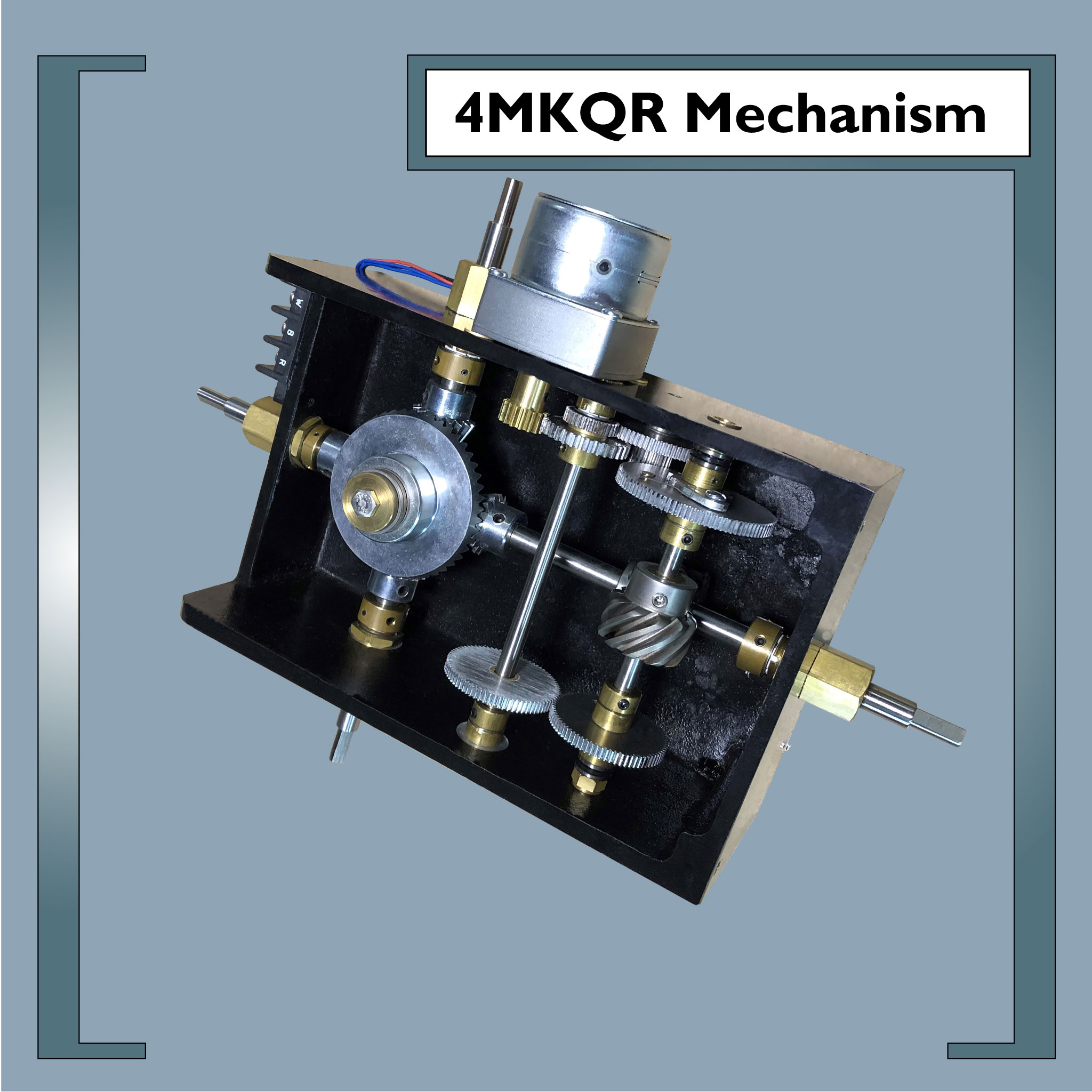

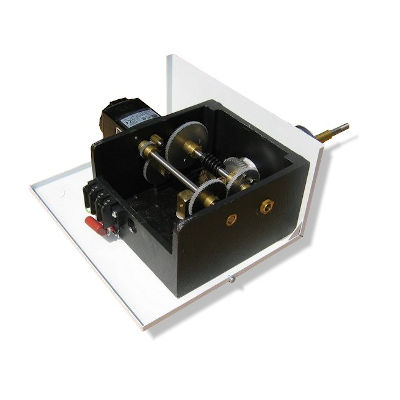

The National Time 4M Series clock mechanisms are the strongest in the industry due to its cast aluminum box construction. This worm gear transmission design outperforms those with parallel plates to withstand extreme forces that may be encountered in service. The 4M mechanism is driven by a permanent magnet, 120V 50Hz or 60Hz synchronous gear. These mechanisms offer mounting options to suit all applications with dial sizes up to 11’ diameter. Custom shaft lengths can be provided to meet specific project requirements.

Common Features

Dial sizes to 11’

Rugged box construction

Cast Aluminum housing

Shaft extension to eliminate illuminated dial shadows

Through wall applications to 24" thick

Front mount applications

UL Listed

Manufactured in the U.S.A.

Variations

-

4MR

The 4MR employs an innovative transmission and reversible motor that will advance the hands 10 times speed for correction. Time correction can be controlled remotely using a 970 or 980 series manual control. A Master Clock Controller will provide automatic time corrections for daylight saving and power outages.

-

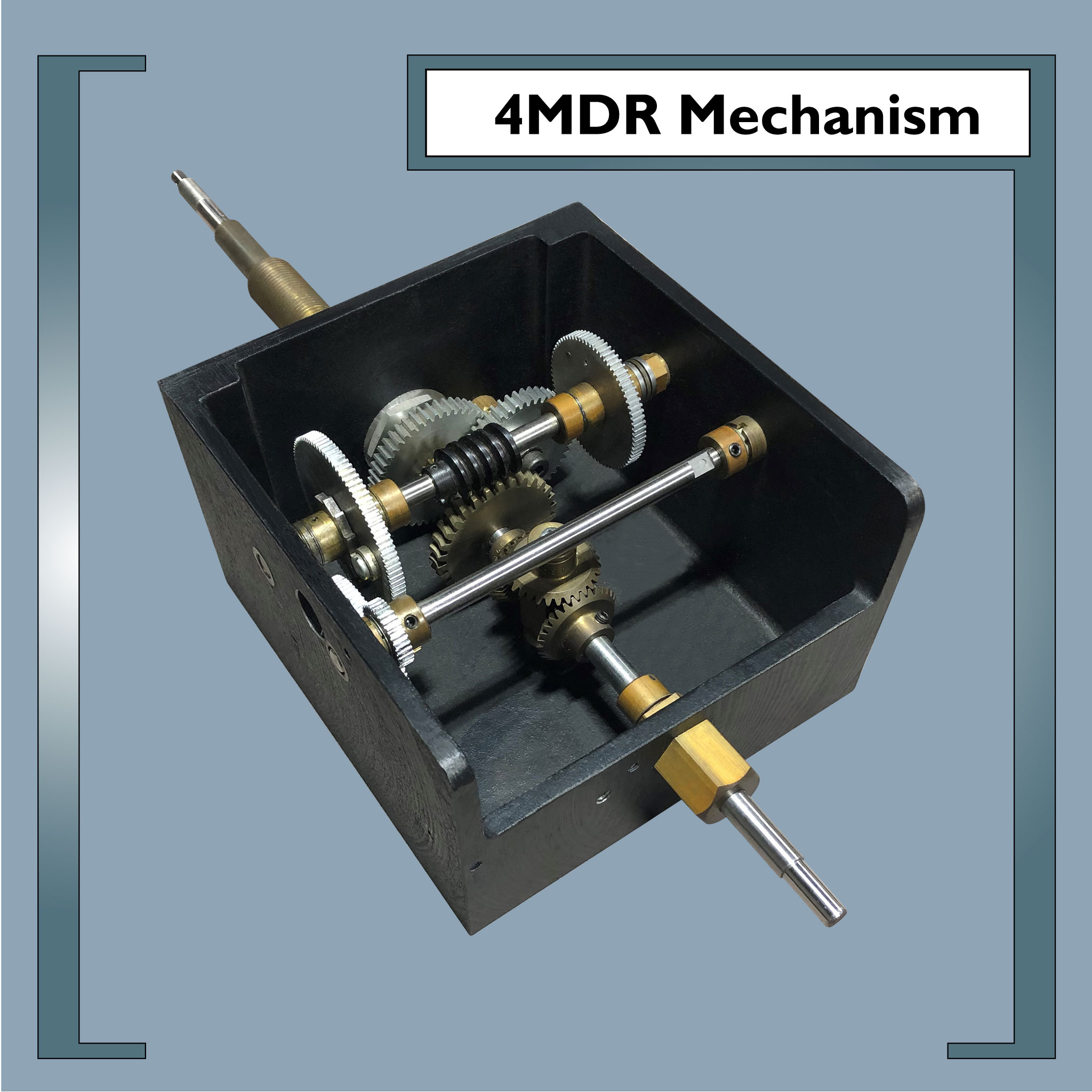

4MDR

The 4MDR is a double face version of the 4MR. A single mechanism drives back-to-back clock dials with spacing between 15” and 24” with appropriate shaft selection

-

4MI

The 4MI minute impulse advances incrementally each minute utilizing a single direction motor. An MC3 Master Clock Controller is required for operation and provides automatic correction. The 4MI will not drift when employed in countries that do not regulate power line frequency or installations that may have generator backup power. An MC3 Master Clock with the 4 circuit expansion switches allows user to remotely adjust up to 4 clocks independently during installation or repair.

More Details

The National Time 4M Series clock mechanisms are the strongest in the industry due to its cast aluminum box construction. This worm gear transmission design outperforms those with parallel plates to withstand extreme forces that may be encountered in service. The 4M mechanism is driven by a permanent magnet, 120V 50Hz or 60Hz synchronous gear. These mechanisms offer mounting options to suit all applications with dial sizes up to 11’ diameter. Custom shaft lengths can be provided to meet specific project requirements....